Modern innovation meets old-school reliability

The V-Series design is the most recent, state-of-the-art self cleaning screen filtration technology available today. The complexity and cleaning efficiency of any self-cleaning screen filter is in the mechanical system that drives the cleaning process. The new patented Infinity Drive™ mechanism is the simplest and most efficient in design resulting in:

- Minimal water wastage

- Fewer moving parts (no limit switches or pistons reversing the cleaning mechanism)

- Simpler controls

- Lowest flush flow available

- Greater cleaning efficiency

- Lower maintenance requirements

The V-Series’ 5 to 30 second flush cycle is automatically initiated when a pressure differential across the screen increases to 50kPa. The filter remains on line, and the filtration process remains uninterrupted during the cleaning process. The flush discharge is the lowest available resulting in minimal waste.

The low cost solution that works

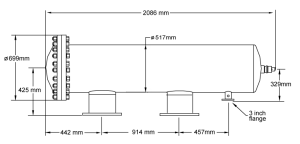

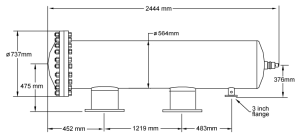

VAF filters remove silt, scale, sand, dirt and organic matter such as algae from virtually all types of water sources including process water, cooling tower water, wastewater and more. The V-Series of filters offers a lower-cost solution for filtering suspended particles 80 micron and larger. The recommended filtering flow rates of the filters range from 2 Lps up to 345 Lps, with a pressure range of 205 kPa to no greater than 1035 kPa.

The V-Series filters are constructed in the USA to ASME code and are designed to incorporate a broad range of construction materials, and pressure and temperature options. The V-Series filters come in a variety of sizes to suit a wide range of applications. Applications include:

- General industrial

- Steel manufacturing

- Power generation

- Chemical and petrochemical

- Refinery

- Food processing

- Mining

- Water/wastewater

- Irrigation

V-Series filters are available as integrated components or as a complete skid-mounted filtration solution.