FAQ’S – Your questions answered

Want to know more about VAF’s V-Series Filters? View our frequently asked questions to find information on the range, why you should choose a V-Series and how they work.

How do the V-Series Filters work?

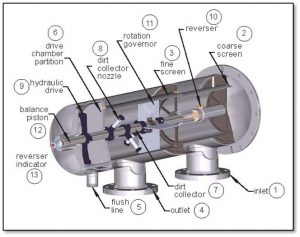

Please refer to the cutaway of the V-Series filter to the left.

Please refer to the cutaway of the V-Series filter to the left.

Dirty water enters the filter though the inlet (1) and then passes through the coarse screen (2) from the outside in. It flows from the inside of the coarse screen to the inside of the fine screen and then passes though the fine screen (3) from the inside out. Dirt is collected on the inside surface of the fine screen. The clean filtered water then exits through the filter outlet (4) and on into the system.

As the dirt or cake builds up on the inside surface of the fine screen, the pressure drop across the screen increases. When the pressure drop, (the DP or differential pressure) reaches a preset level (7 psi), the filter controller starts a flush cycle by opening a flush valve on the flush line (5). This flush valve exhausts the drive chamber to atmosphere at “0” psi.

The flush line (5) is connected to the drive chamber which is separated from the filtration chamber by a drive chamber partition (6). However, the dirt collector (7) (a hollow pipe with dirt collection nozzles) extends through the partition (6), thus providing a “path” from the dirt collector nozzles (8) through the hydraulic drive (9), into the drive chamber and out the flush line (5) to atmosphere. The pressure around the dirt collector nozzle (8) is the pressure inside the filter and as water flows through the “path”, it drops to “0” psi when it leaves the flush line. This creates an aggressive “suction” at the dirt collector nozzle (8) opening. The dirt collector nozzle (8) clearance at the fine screen (3) is very small. So, the extreme low pressure at the nozzle opening creates a backflow which “sucks” the dirt from the fine screen (3).

The hydraulic drive (9) has jets on opposite sides near its ends. Water jetting out of these openings (coming from the dirt collector nozzles (8)) creates a reaction force (like a pin wheel) which rotates the drive (9) and the dirt collector (7). As the dirt collector (7) rotates, each dirt collector nozzle (8) cleans a band on the fine screen (3).

As the dirt collector (7) rotates, the reverser (10) which works like a level winder on a fishing reel, causes the hydraulic drive (9) / dirt collector (7) / dirt collector nozzle (8) assembly to move back and forth. The rotation governor (11) helps control the rotation speed of the of the dirt collector (7) assembly. The balance piston (12) helps balance the transverse pressure on the assembly, and powers the reverser indicator (13) which provides visual indication of the dirt collector (7) assembly movement showing the entire cleaning system is operating properly during the rinse cycle.

After a preset time, the flush valve closes and the rinse cycle is complete. Very little rinse water is used for each rinse. Please note the filter continues to supply water to the system during a rinse cycle.

See it in action and watch the Video

V-Series Filters – the basics

V-series self-cleaning filters offer the greatest water savings in the industry.

The revolutionary self-cleaning screen filtration technology will increase cleaning efficiency, minimise water usage and reduce your maintenance requirements.

- Cutting edge screen filtration technology

- Cleaning cycle begins at 50kPa differential across the screen

- 10 to 30 seconds per flushing cycle

- The patented Infinity Drive™ mechanism is the simplest and most efficient in design

resulting in:- Fewer moving parts (no limit switches or pistons reversing the cleaning mechanism);

Simpler controls; - Reduced flush flow;

- Greater cleaning efficiency;

- And lower maintenance requirements.

- Fewer moving parts (no limit switches or pistons reversing the cleaning mechanism);

- Filtration process remains uninterrupted during the cleaning process

- The flush discharge is the lowest in the industry – minimal waste

- A range of screen sizes from 15 to 1500 micron

- Flow range – 2 to 245Lps

- Pressure range – Minimum 205kPa to Maximum 1035kPa

- Stainless steel housing and screens

- No electrical parts – all mechanically driven

- Ideal for a wide range of applications

What are the applications of the V-Series?

What are the Flow Rates of the V-Series?

What are the Flush cycle specifics?

What are the uses of the VAF Filters?

Who are the manufacturers and distributers?

Why should you choose the V-Series Filter?

The V-Series design features the latest, state-of-the-art self-cleaning screen filtration technology. The complexity and cleaning efficiency of any self-cleaning screen filter is in the mechanical system that drives the cleaning process. The patented Infinity Drive™ mechanism is the simplest and most efficient in design resulting in:

- Minimal water wastage

- Fewer moving parts (no limit switches or pistons reversing the cleaning mechanism)

- Simpler controls

- Lowest flush flow available

- Greater cleaning efficiency

- Lower maintenance requirements

V-Series filters are constructed in the USA to ASME code and are designed to incorporate a broad range of construction materials, pressure and temperature options.

V-Series filters are available as integrated components or as a complete skid-mounted filtration solution.